About Us

Highly Engineered Solutions

Our Founder, John Rector, grew up in a college town. He earned his machine shop merit badge with the machine shop instructor at the University of Illinois. The instructor then invited the 5 Boy Scouts to return on Saturdays if they wanted to learn more. The only one to accept the offer was Johnny Rector. This scout earned a college degree in Machine Shop Technology, for free, before he could drive a car.

At age 26 he was leading a dozen tool and die makers at the the DuPont Plant in Kansas City. They made tools to form 16mm cannon cartridges for the war. He received his first promotion because he could do square root in his head. DuPont sent him out to the “Manhattan Project”, a secret weapons plant in the Eastern Washington desert. He arrived on his Harley Davidson. Here, he designed the process to sinter aluminum-boron, which was control rod material for the historic B Reactor.

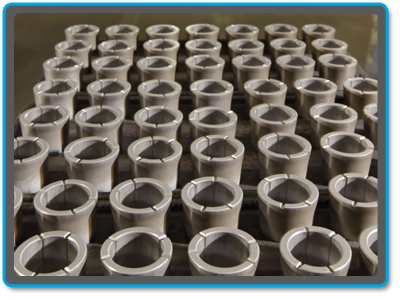

It was the sintering process that captured his attention. Rather than machine parts, he could just press powder into shapes and sinter them. Western Sintering became his life work. The facility moved from the family basement to 28 acres, and expanded from one building to three.

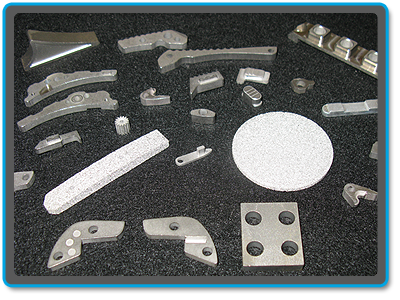

Today Western Sintering Co. Inc. is an ISO 9001:2015 certified powder metal manufacturing company that specializes in part sourcing options out of powder metal. Located in Richland, Washington, we provide highly engineered solutions out of ferrous and copper based materials. Alloy steel, stainless steel, copper, brass, nickel silver (white brass) and bronze.

Generally, if a customer has a part that is a good “fit” for Powder Metal Manufacturing, we can often find cost savings over competing manufacturing methods at quantities as low as 1000-2000 parts annual usage. As well as being able to work well with lower quantities, we also have the capacity to deal with large part runs into the 100,000 to 2,000,000 parts annual usage requirements.

We pride ourselves in working efficiently with customers and should you have a part that you would like to have quoted for our process, all we need is a material requirement and a dimensioned print/drawing. Then we can generally tell you within 15-20 minutes of looking over the drawing whether or not the part is a good fit for our process. If it is, we can then proceed to work out a quote for parts and tooling. If it’s not a good fit for our process, we usually can help steer you in a direction of manufacture that is better suited for the application.