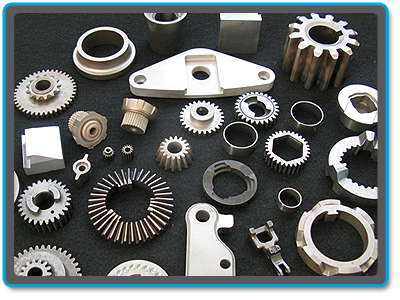

Powder Metal Manufacturing

Reduce Manufacturing Costs

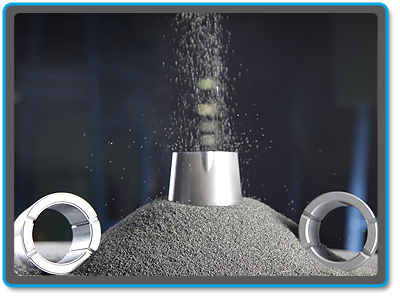

Powder metallurgy is the process of blending fine powdered materials, pressing them into a desired shape or form (compacting), and then heating the compressed material in a controlled atmosphere to bond the material (sintering).

The four basic steps of the powder metallurgy process:

- Powder Manufacture

- Powder Blending

- Compacting

- Sintering

Compacting is generally performed at room temperature, and the elevated-temperature process of sintering is usually conducted at atmospheric pressure. Optional secondary processing often follows to obtain special properties or enhanced precision. The use of powder metal technology bypasses the need to produce the resulting products by metal removal processes, thereby reducing manufacturing costs.